Companies find that their environment is constantly changing and they are constantly trying to improve business processes. There are multiple ways to tackle process improvements such as Continuous Improvement (CI), Total Quality Management (TQM), Lean and Six Sigma.

Companies find that their environment is constantly changing and they are constantly trying to improve business processes. There are multiple ways to tackle process improvements such as Continuous Improvement (CI), Total Quality Management (TQM), Lean and Six Sigma.

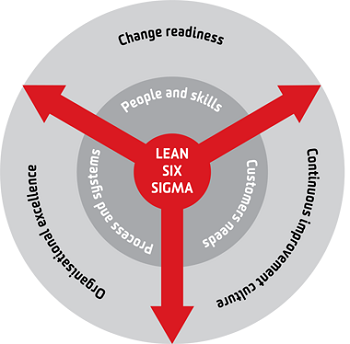

This article describes best way to tackle business problems by combining two philosophies – Lean and Six Sigma. Termed Lean Six Sigma – it benefits customers, employees and ultimately the company.

What is Lean Six Sigma?

- Lean = simplify by eliminating non-value-add activities

- Six Sigma = perfect by reducing variation

This enables companies to create business processes that benefit both customers and business needs. The key is in understanding what customers want and finding the most efficient way to deliver those within the time-frame and quality they expect. Note that the customers are almost always internal and external.

Lean Six Sigma can be used to evaluate and improve ALL business processes. Business process is the one that can be both:

- repeated – examples are hosting a customer visit, generating a report, providing status on a project and recording how you spend your time or designing / building your product and

- measured – must be completed within a certain time frame, sufficiently detailed for other people to conduct additional work.

A value-add process has 3 main characteristics

- The customer must care about the step,

- It has to change the thing being processed and

- It must be done right the first time

If the step is not adding value, it should be minimised or scrapped all together.

Value Stream Map

The flow of value-added and non-value-added steps that leads to the end product represents your value stream. Adding information such as how long each step takes and how long the process simply waits in between steps begins to create the value stream map.

All of this analysis helps teams evaluate all non-value-add steps and process inefficiencies. In Lean Six Sigma this is called waste or doing something that is not really necessary. Some examples of waste are:

- Having to do work a second time

- bottlenecks that make others have to wait

- Creating an end product that does not get used or gets rejected and

- Playing telephone tag

- Waste in overtime cost or lost time

- A ‘hidden’ waste – small waste what happens multiple times daily to multiple employees

COPQ – Cost of Poor Quality

By identifying the value-add and non-value-add and then isolating the waste you can calculate your COPQ in the process. Converting the COPQ to a dollar amount starts to show you impact that ultimately impacts earnings-per-share (EPS), improving the bottom line.

5 Phases of the DMAIC methodology

- Define

- Measure

- Analyse

- Improve and

- Control

DMAIC is used whenever there’s a repeatable process that can be measured.

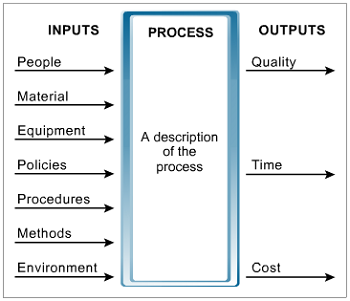

Define – get a short description of the problem as defined by customer or business impact that are critical to customer and quality of the product. During this process an Input-Process-Output (IPO) diagram is commonly used. IPO included key output components and key input components.

Define – get a short description of the problem as defined by customer or business impact that are critical to customer and quality of the product. During this process an Input-Process-Output (IPO) diagram is commonly used. IPO included key output components and key input components.

Measure – In the measure phase the team begins to review the things that actually happen today and is called ‘as-is’ status. Measure phase is also the time to begin the value-add analysis. After measuring value we need to find out how good of a job we’re doing.

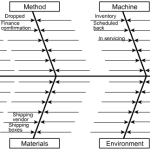

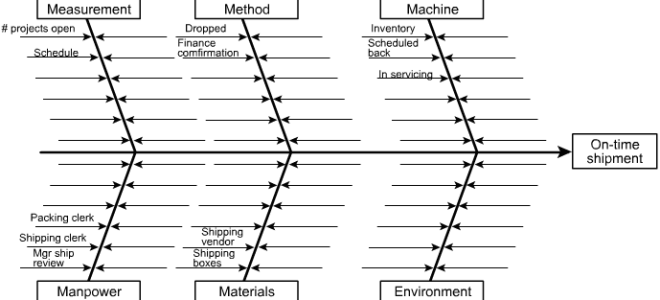

Analyse – In the analyse phase the team will look at the ways to improve the output of the process that is critical to customer. During this phase you will likely use a ’cause-and-effect’ diagram.

Improve – This phase focuses on eliminating waste where possible and implement process change to cater for customer demands and requirements. This is when the Lean Six Sigma team tests the new process on the representative subset of users. Once the new process has proven to be better, the change can be rolled out to all the process users. Change management is then implemented which includes communication and training phases.

Improve – This phase focuses on eliminating waste where possible and implement process change to cater for customer demands and requirements. This is when the Lean Six Sigma team tests the new process on the representative subset of users. Once the new process has proven to be better, the change can be rolled out to all the process users. Change management is then implemented which includes communication and training phases.

Control – The team develops the plan that the business process owner can use to ensure the improvements are sustained. This plan allows the process owner to be more self-sufficient.